In the modern logistics and storage industry, the demand for reliable and consistent pallet solutions continues to grow. With the expansion of global trade and the rising need for efficient material handling, businesses are seeking tools and systems that can support their operational goals. Among these, the Spaill Pallet Mould has emerged as a practical and dependable option, offering numerous applications across different areas of logistics and storage management.

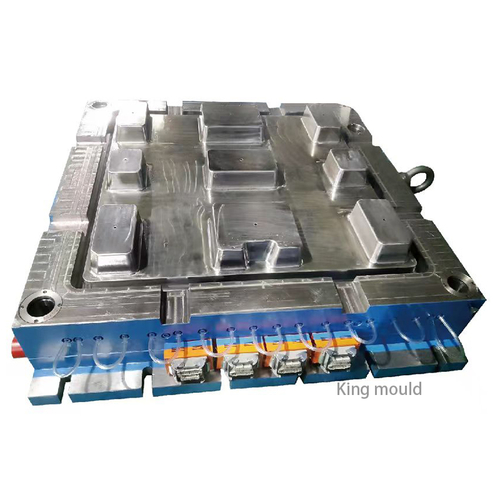

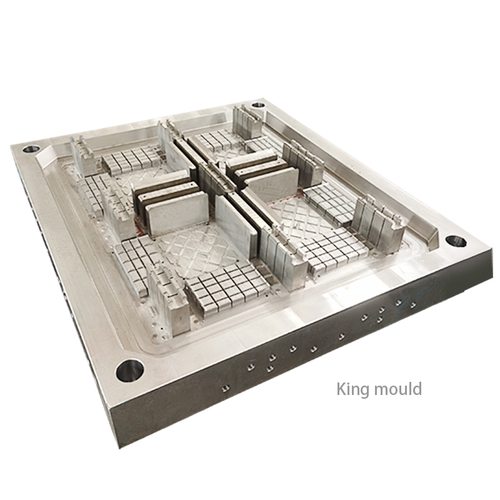

The Spaill Pallet Mould is specifically engineered to produce sturdy pallets designed for the movement, storage, and protection of goods throughout the supply chain. Its application begins in production facilities, where it is used to create pallets tailored to specific load capacities and operational environments. Whether handling lightweight consumer products or heavy industrial equipment, the Pallet Mould provides businesses with a versatile solution that ensures each pallet is manufactured to meet predefined standards.

One of the primary applications of the Spaill Pallet Mould is in warehouse storage systems. Pallets produced using this mould are designed to offer consistent sizing and strength, which are essential for enhancing space in shelving units and racking systems. The use of uniformly produced pallets enables businesses to organise goods more efficiently, reducing wasted storage space and improving inventory management. This consistency also allows for safer stacking and easier tracking of stock within large storage facilities.

Another important use of the Spaill Pallet Mould lies in distribution centres, where pallets play a central role in the handling and sorting of goods for shipment. Distribution hubs often deal with high volumes of products moving in and out daily. By using pallets created with a Pallet Mould, businesses can streamline their material handling operations, ensuring that products are securely positioned for loading onto trucks and containers. The strength and durability of these pallets help prevent product damage during transport, reducing waste and operational costs.

The Spaill Pallet Mould is also widely applied in cold storage facilities, where temperature-sensitive goods require special handling conditions. Pallets produced through this mould are made from materials that can endure server temperatures, making them suitable for storing perishable items such as food, pharmaceuticals, and chemicals. The ability to maintain structural integrity in both freezing and humid environments highlights the value of the Spaill Pallet Mould for businesses operating within these specialised sectors.

Export logistics is another area where the Spaill Pallet Mould finds significant use. Global shipping regulations often require pallets to meet certain standards to prevent contamination and facilitate safe transport. The Pallet Mould allows manufacturers to produce pallets that comply with international guidelines, making it easier for companies to move products across borders. This capability reduces delays in customs inspections and supports smoother international trade operations.

Manufacturers of consumer goods also benefit from the Spaill Pallet Mould in their internal logistics processes. Pallets produced using this mould are used to transport raw materials to assembly lines and move finished products to packaging and distribution points. The mould’s ability to produce consistently sized pallets improves workflow efficiency by reducing the risk of disruptions caused by incompatible pallet dimensions.

Furthermore, the Spaill Pallet Mould is valued in the automotive and heavy machinery industries, where the transport of bulky or oddly shaped components requires custom pallet solutions. The mould can be configured to create pallets of varying sizes and shapes, ensuring that parts and equipment can be moved safely and securely through manufacturing plants and storage facilities. This flexibility is especially useful in sectors where product specifications frequently change.

Recycling and sustainable logistics initiatives have also integrated the Spaill Pallet Mould into their processes. The mould’s design allows for the use of recyclable materials, contributing to eco-friendly practices within the supply chain. Many companies now use pallets created with a Spaill Pallet Mould multiple times before recycling them at the end of their service life, reducing environmental impact and lowering packaging costs.

In emergency logistics and disaster relief operations, pallets made with the Spaill Pallet Mould are used to transport medical supplies, food, and essential equipment to affected areas. The durability of these pallets ensures that critical items can be delivered safely under difficult conditions. Their consistent design allows for quick loading and unloading, which is essential during time-sensitive relief efforts.

English

English عربى

عربى

.jpg?imageView2/2/w/500/h/500/format/jpg/q/100)