China Sale Plastic Injection Moulded Pallets Mould Supplier

In the modern manufacturing landscape, efficiency and cost-effectiveness are paramount. One key element that has seen significant innovation is the plastic pallet mould. This piece of equipment plays a crucial role in the production of plastic pallets, which are essential for various industries, from logistics to manufacturing. This article explores the innovative solutions associated with China Plastic Pallet Moulds and how they are transforming the industry.

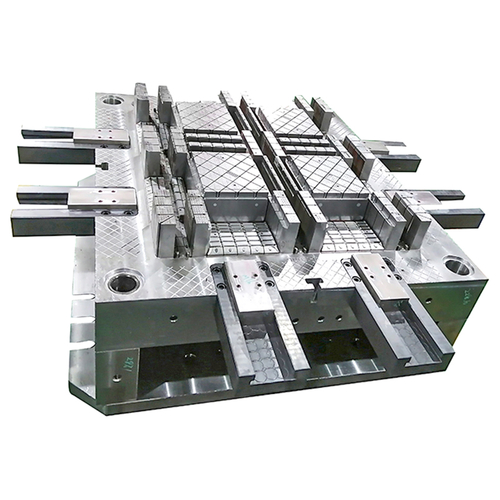

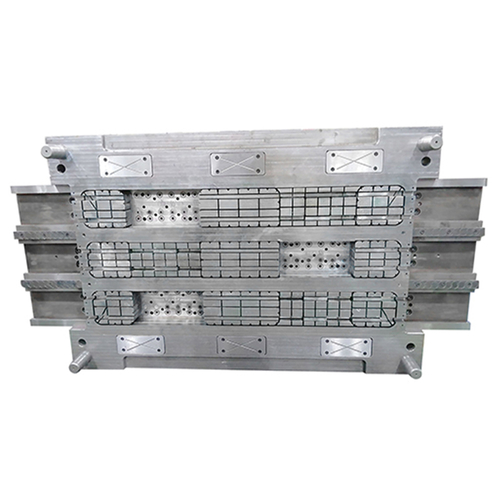

A plastic pallet mould is a specialized tool used in the manufacturing process to create plastic pallets. These moulds are designed to shape molten plastic into durable and functional pallets that meet specific industry standards. The development and refinement have led to significant advancements in pallet design, material efficiency, and overall production quality.

The Role of Plastic Pallet Mould in Modern Manufacturing. They are engineered for high precision and efficiency. Advances in mould design and manufacturing techniques have enhanced the accuracy of pallet dimensions and weight distribution. This precision ensures that each pallet produced is consistent and meets the stringent quality requirements of various industries.

One of the major innovations in plastic pallet mould technology is the optimization of materials used in the production process. Improved mould designs enable the use of less plastic while maintaining the strength and durability of the pallets. This not only reduces material costs but also supports environmental sustainability by reducing plastic waste.

Innovations in plastic pallet moulds have led to the development of pallets that are more resistant to wear and tear. Advanced moulding techniques, such as injection moulding and blow moulding, allow for the production of pallets with strength and longevity. This enhancement reduces the frequency of replacements and maintenance, offering long-term cost savings.

Plastic pallet moulds can be customized to produce pallets with specific features tailored to different applications. This includes variations in size, load capacity, and surface texture. Such versatility makes plastic pallets suitable for a wide range of industries, from food and beverage to pharmaceuticals and automotive.

Key Innovations in Sale Injection Moulded Pallets Technology. They often feature multi-cavity designs that allow for the simultaneous production of multiple pallets. This innovation significantly increases production capacity and reduces cycle times, making manufacturing processes more efficient and cost-effective.

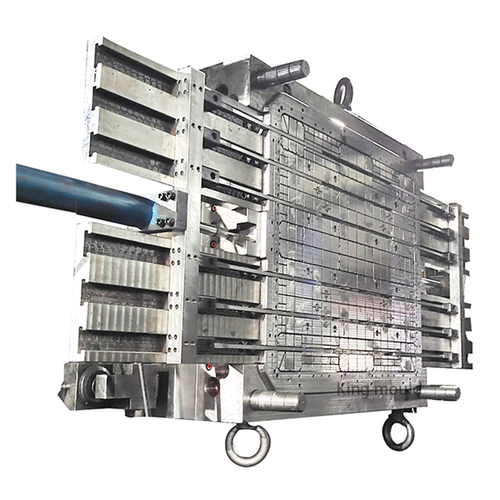

The integration of automation into plastic pallet moulding systems has revolutionized the industry. Automated systems streamline the moulding process, from loading and unloading to cooling and ejection. This automation not only improves production speed but also enhances precision and reduces labour costs.

Efficient cooling systems within plastic pallet moulds are crucial for maintaining the quality and consistency of the finished products. Innovations in cooling technology, such as conformal cooling channels, enable more effective heat dissipation. This results in shorter cycle times and improved pallet quality.

The development of advanced mould materials has also played a significant role in improving Moulded Pallets Supplier performance. High-strength, heat-resistant alloys and coatings enhance the durability of the moulds, allowing them to withstand the rigours of repeated use and high-temperature processing.

Looking ahead, the plastic pallet mould industry is likely to see continued innovation driven by technological advancements. Emerging trends include the integration of smart technology and data analytics into moulding processes, allowing for real-time monitoring and optimization. Additionally, the development of biodegradable and eco-friendly materials for pallet production aligns with the growing emphasis on sustainability.

Innovative solutions with plastic pallet moulds are reshaping the manufacturing landscape by offering increased efficiency, cost savings, and product quality. The advancements in mould design, materials, and automation are setting new standards for the production of plastic pallets. For businesses looking to stay ahead in a competitive market, embracing these innovations is key to unlocking significant value and achieving long-term success.

English

English عربى

عربى