In the world of logistics, efficiency, safety, and cost-effectiveness are critical components of successful operations. A key element in achieving these goals is the use of high-quality pallets for transporting goods. Injection moulded pallets are gaining increasing popularity in logistics due to their numerous advantages over traditional wooden or metal pallets. These pallets, made using the injection moulding process, provide a range of benefits that can enhance both safety and efficiency in logistics operations. This article explores how Custom injection moulded pallets are contributing to improvements in logistics and supply chain management.

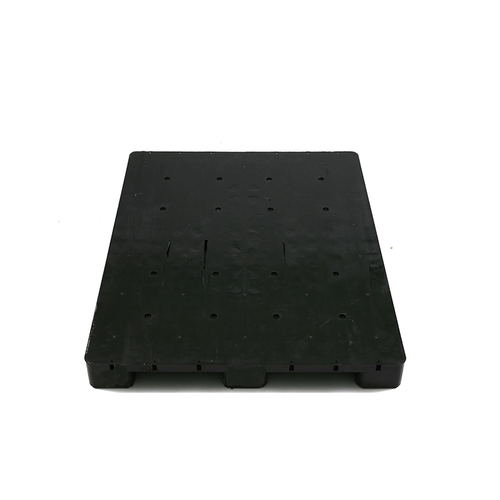

One of the primary benefits of injection moulded pallets is their durability. These pallets are designed to withstand harsh conditions and heavy loads, making them highly reliable for logistics operations. Unlike wooden pallets, which can deteriorate over time due to exposure to moisture, pests, or physical wear, injection pallets are resistant to environmental factors. They do not splinter, warp, or absorb moisture, ensuring that they remain in good condition for longer periods. The longevity of these pallets reduces the need for frequent replacements, resulting in long-term cost savings for logistics companies. Furthermore, the durability of injection moulded pallets contributes to fewer instances of product damage during transit, enhancing the overall efficiency of the supply chain.

Safety is a top priority in any logistics operation, and the use of injection moulded pallets plays a crucial role in reducing workplace hazards. Traditional wooden pallets can have sharp edges, nails, or splinters that pose safety risks to workers handling them. On the other hand, injection pallets are designed with smooth, uniform surfaces and rounded edges, reducing the risk of injury during handling. Workers are less likely to sustain cuts or abrasions when moving or stacking these pallets, promoting a safer working environment. The sturdy and stable design of OEM Plastic Mould Makers also helps to reduce the chances of pallets collapsing or tipping over during transportation, further enhancing safety in logistics operations.

In logistics, the stability of the load being transported is essential to ensure safe delivery and prevent damage to goods. Injection moulded pallets offer load stability compared to traditional pallets. The consistent shape and strength of these pallets ensure that goods are securely placed and transported without shifting during transit. This level of stability is particularly important when moving fragile or high-value items, as it reduces the likelihood of product damage. Additionally, injection moulded pallets are lightweight and easy to handle, allowing workers to load and unload goods more quickly and safely. The smooth surface and precise design make them compatible with automated systems, further improving efficiency in warehouses and distribution centers.

Sustainability is becoming increasingly important in logistics, and injection moulded pallets offer several environmental benefits. Many of these pallets are made from recyclable materials, meaning they can be reused or repurposed at the end of their life cycle. This reduces the environmental impact associated with pallet disposal and helps to reduce waste in the logistics supply chain. Unlike wooden pallets, which contribute to deforestation and often end up in landfills, injection pallets can be recycled, contributing to a more sustainable circular economy. Additionally, the production process for Crate Mould Makers is more energy-efficient compared to the manufacturing of wooden pallets, further supporting sustainability efforts within the logistics industry.

Effective space utilization is a crucial aspect of logistics operations, particularly in warehouses. Injection moulded pallets are designed for efficient stacking, which helps enhance storage space. Their uniform shape and precise measurements allow for easy stacking, whether in racking systems or during transport. This feature is particularly beneficial in warehouses that need to optimize available space. The ability to stack injection moulded pallets securely reduces the amount of wasted space, allowing businesses to store more goods in the same area. Additionally, the consistent shape of these pallets makes them ideal for automated handling systems, contributing to greater efficiency in sorting, packing, and storage.

English

English عربى

عربى