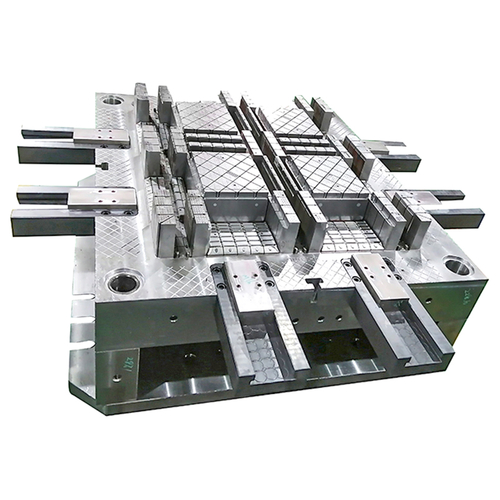

In the fast-paced world of manufacturing, production efficiency is a constant priority. Companies are always looking for ways to optimise their operations, reduce waste, and increase output. One innovation that has garnered attention in recent years is the Spaill Pallet Mould. This specialised mould is transforming how businesses approach pallet production by improving the efficiency of manufacturing processes and offering numerous benefits to industries that rely on pallets for product storage and transportation.

A Spaill Pallet Mould is designed specifically to produce durable and high-quality pallets, which are essential for material handling, logistics, and distribution across many sectors, including food, retail, automotive, and pharmaceuticals. Traditionally, pallets were made using labour-intensive methods, which were not only time-consuming but also costly. However, the introduction of the Pallet Mould has streamlined this process, significantly improving both speed and precision in production.

One of the main advantages of the Spaill Pallet Mould is its ability to automate much of the production process. Unlike manual pallet construction, which requires substantial labour input and often results in inconsistencies, the use of a Pallet Mould ensures that each pallet is produced with uniformity and precision. This consistency helps reduce errors and variations in the final product, which is essential in industries where standardisation is key. As a result, businesses can save both time and money while meeting high production standards.

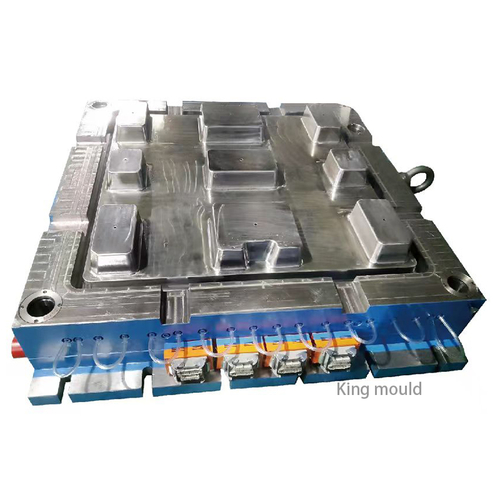

The Spaill Pallet Mould is also designed to enhance material efficiency. Traditional pallet production often involves a significant amount of wasted materials, either due to human error or inefficient moulding processes. The Pallet Mould optimises material use by ensuring that only the necessary amount of material is used during each cycle. This reduction in material waste not only benefits the environment but also results in cost savings for manufacturers, as less material needs to be purchased and processed.

In addition to improving material efficiency, the Spaill Pallet Mould enhances the overall speed of production. Manufacturing times are significantly reduced, allowing businesses to produce larger quantities of pallets in a shorter time frame. This increased throughput is particularly important for industries with high-volume demands or those working with tight deadlines. By speeding up the production process, companies can respond to customer needs more quickly and maintain a steady flow of goods, all while keeping costs down.

Another key benefit of the Spaill Pallet Mould is its versatility. This mould is designed to accommodate a variety of pallet sizes and specifications, allowing businesses to produce different types of pallets to suit their specific needs. Whether it's a standard-sized pallet for shipping or a custom-designed pallet for specialised purposes, the Spaill Pallet Mould can be adjusted to meet the requirements of different industries. This flexibility allows manufacturers to cater to a wide range of clients and provides a competitive edge in the market.

The durability of pallets produced with the Spaill Pallet Mould is another significant advantage. Pallets are subjected to rough handling during transport, so it's essential that they can withstand wear and tear. The Spaill Pallet Mould produces robust pallets that are designed to endure harsh conditions. This ensures that pallets last longer, reducing the need for replacements and maintenance costs. For businesses, this means fewer disruptions to the supply chain and a more reliable product that enhances operational efficiency.

Sustainability is becoming an increasingly important factor in the manufacturing industry, and the Spaill Pallet Mould plays a role in promoting eco-friendly practices. The precise design of the mould reduces material waste, and the durability of the pallets extends their lifespan, resulting in fewer pallets being discarded after use. Moreover, many of the materials used in the production of pallets are recyclable, so the entire process can contribute to a more sustainable approach to manufacturing.

The ease of maintenance and cleaning associated with the Spaill Pallet Mould is another feature that contributes to its overall efficiency. Pallet moulds can accumulate dirt and debris over time, which can affect the quality of the final product. However, the Spaill Pallet Mould is designed for easy maintenance, reducing downtime for cleaning and repairs. This streamlined approach helps ensure that the production process remains uninterrupted and that the moulds are always in ideal condition for use.

English

English عربى

عربى