Wherever you are now, if you look around you will see plastic. If you were reading this article on a computer, you might have touched some. Plastics have revolutionized manufacturing and continue to do so every day. New uses for existing plastics are being discovered, and new plastics are being developed to meet demand. All the things you see around you need to take their shape in one way or another. This is usually accomplished through one of several molding methods, and here are some of them, and why they were chosen.

compression molding

Compression molding is achieved when plastic is placed into a mold. The mold is divided into two parts, heated and joined under great pressure, which in turn forces the plastic into the shape of the mold. The mold is held in place until the plastic cures, after which it can cool and complete the molded part. Items formed using compression molding include things like car bumpers and rubber boots. This is a very useful way to shape large shapes.

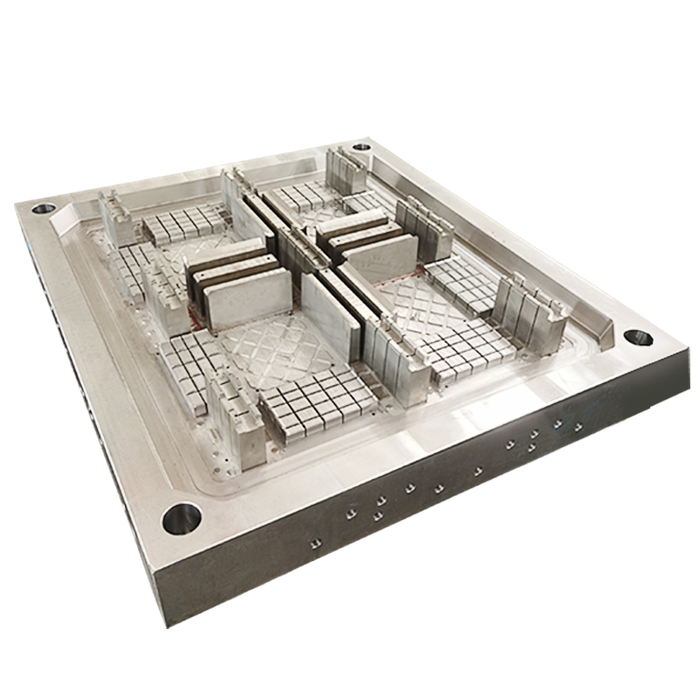

injection pallet mould is probably the most widely used moulding technique. This is because it is relatively fast, and because the high pressure used can help obtain finer details of the product. The raw plastic is heated to melt and then pressed into a cold mold under high pressure. Once the plastic cools, the mold is removed and the molded shape is ready for sale. You'll find that your garden furniture, bottle caps and combs are produced this way. This is a great way to mass-produce plastic items, especially since many types of plastic can be used.

Extrusion

Extrusion is used to create simple shapes such as sheets and pipes. Because of the process itself, it is ideal for these types of shapes. Raw plastic, such as pellets or lumps, is heated and turned in a rotating drum. The heated plastic is then forced through the mold, which shapes the plastic. Items made like this all have the same cross-section, such as straws, plastic pipes and hoses, and curtain rails.

Thermoforming

Unlike other forming techniques, a hot sheet or film is stretched over a die to form the desired shape. There are thin gauge and thick gauge variants, the thin gauge gives us items like disposable cups, and the thick gauge gives us items like car doors and plastic trays.

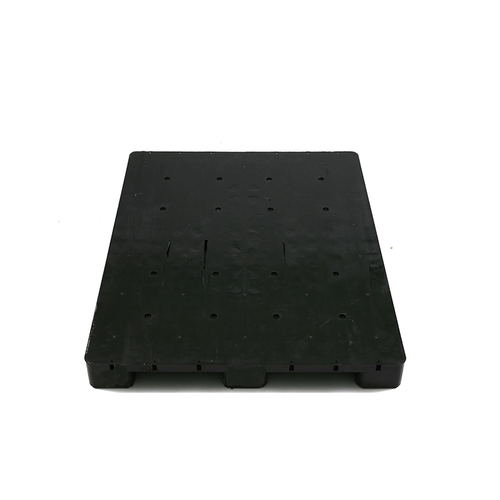

Sophisticated Technology Heavy Duty Pallet Mould

Sophisticated Technology Heavy Duty Pallet Mould

Usage:

Plastic pallets are commonly used for the commercialization of high rotation and/or bulky products. These pallets reduce the risk of damaging a product by moving it from one point to another. This is because you will only lift the platform without touching the product.

Advantage of plastic pallet:

easier to transport.safer for everyone.take up less space.more flexible and versatile.have a longer lifespan than wood pallets

English

English عربى

عربى